Key Takeaways

- Understand the advantages and disadvantages of various wheel types, including polyurethane and steel, for your warehouse requirements.

- Evaluate load requirements, floor surfaces, and the potential impact of noise or marking concerns before making a decision.

- Maintain regular inspections and safety protocols to extend the life spans of wheels and pallet jacks.

Table of Contents

- Introduction

- Types of Pallet Jack Wheels

- Factors to Consider When Choosing Wheels

- Maintenance and Safety Tips

- Conclusion

Selecting the right pallet jack wheels is crucial for efficient warehouse management. Proper wheels not only support seamless movement of pallets but also reduce maintenance costs and increase employee safety. The proper selection can make all the difference in protecting your floor surfaces, improving productivity, and ensuring long-term equipment reliability.

Different warehouses and industrial settings require specific pallet jack wheels based on traffic levels, environmental factors, and the type of goods handled. It’s essential to consider the primary factors—such as load capacity, material durability, and environmental impact—before making a purchasing decision. These factors will ultimately influence the ease of material handling and the longevity of your equipment investment.

Many facilities overlook the impact that wheel material and size can have on daily operations. Whether you’re running a distribution center, a retail warehouse, or a manufacturing plant, informed wheel selection can help mitigate workplace injuries and lower downtime related to equipment failure. Deliberate attention to wheel features is a simple way to ensure smooth handling operations and personnel safety.

In this guide, you’ll learn the distinguishing features of commonly used pallet jack wheels, what to look for in your specific warehouse environment, and simple maintenance routines that reduce long-term costs. By understanding all relevant factors, your investment will yield sustained efficiency and protection for both your personnel and facility.

Types of Pallet Jack Wheels

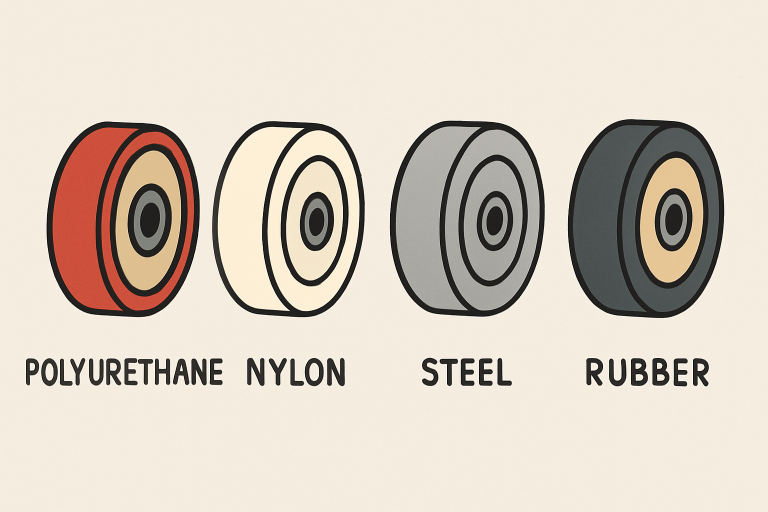

The efficiency, safety, and ease of your material handling tasks hinge significantly on the type of pallet jack wheel installed. Here are the four most common types:

Polyurethane Wheels

Polyurethane wheels are among the most widely used because they deliver a quiet, smooth ride and leave no marks behind, which is essential in facilities with finished or coated floors. They’re ideal in busy, noise-sensitive environments or retail settings. However, on consistently rough surfaces, they may deteriorate more quickly than harder options.

Nylon Wheels

Nylon wheels are engineered for durability and strength. Their rigid design makes them suitable for heavy loads and surfaces littered with debris. They boast chemical resistance, making them fit for industrial applications. Due to their hardness, they generate more noise and can scuff up finished flooring; therefore, they’re best reserved for backrooms or industrial zones out of public view.

Steel Wheels

When it comes to extremely heavy-duty performance, steel wheels are unmatched. Their toughness supports substantial weight and resists damage from harsh environments, including those with metal shavings or uneven surfaces. However, they are noisy in operation and can gouge or scratch delicate warehouse floors, making them unsuitable for customer-facing or sensitive areas.

Rubber Wheels

Rubber wheels strike a balance between traction and comfort by improving grip and minimizing rolling noise. They’re especially effective on slippery or slightly uneven ground but may trade off longevity and experience higher rolling resistance than harder materials.

Factors to Consider When Choosing Wheels

Selecting the best wheels involves more than choosing the right material. Consider these crucial factors before making your purchase:

Load Capacity

Pallet jack wheels must reliably support the maximum weight they’ll be moving. As a general rule, always select wheels with a higher weight capacity than your heaviest regular load. Industry standards suggest exceeding the maximum load by at least 20% to allow a safety margin. Overloading is a significant contributor to premature wheel failure and can lead to injuries or damage to goods.

Floor Conditions

The type of surface at your facility plays a pivotal role. For smooth, painted, or tiled floors, polyurethane wheels are preferred due to their protective and quiet features. If the area is prone to dust, debris, or rough patches, nylon or steel wheels can provide the needed toughness, but at the cost of greater noise and potential floor marking.

Noise Levels

Reducing workplace noise is crucial for employee comfort and overall safety, especially in environments where verbal communication is frequent. Polyurethane and rubber wheels minimize operational noise, while harder wheels, such as nylon or steel, inevitably increase decibel levels. For more insight into healthy noise levels in the workplace, see OSHA’s guide to workplace noise.

Additionally, selecting low-noise wheels can help mitigate long-term hearing strain for employees, particularly in high-traffic warehouse environments. Taking the time to evaluate both acoustic and operational needs ensures the wheels you select support a safer and more productive workspace.

Floor Marking

If aesthetics and floor maintenance are a concern—such as in retail settings or high-traffic areas—opt for non-marking wheels. Polyurethane and certain rubber compounds are ideal for these needs, helping to maintain professional, clean-looking floors that impress both staff and customers.

Maintenance and Safety Tips

Keeping pallet jack wheels in good condition is a straightforward way to ensure uninterrupted and safe warehouse operations. Here’s what you need to remember:

- Inspect wheels regularly for cracks, flat spots, or embedded debris that could impact movement or safety.

- Always verify that the load is stable, balanced, and within wheel capacity before transport.

- Encourage staff to push—rather than pull—the pallet jack to minimize ergonomic strain and the risk of injury.

- Keep travel paths clear and well-lit to avoid navigation hazards.

- Never allow pallet jacks to be used as rides or pushed at unsafe speeds.

Conclusion

Choosing the right pallet jack wheels is more than a matter of preference—it significantly impacts your warehouse’s efficiency, safety, and bottom line. From assessing load capacity and floor type to balancing noise and marking concerns, careful selection ensures operational smoothness and equipment longevity. Prioritize regular wheel maintenance and adhere to best practices to create a safer and more productive warehouse environment.