Table of Contents

- Introduction to Diamond Wire Saw Cutting

- Understanding the Diamond Wire Sawing Process

- Key Advantages of Diamond Wire Saw Cutting

- Applications in Industrial Demolition

- Safety Considerations and Best Practices

- Future Prospects of Diamond Wire Saw Cutting

- Conclusion

Key Takeaways

- Diamond wire saw cutting provides extraordinary precision and minimal environmental impact in industrial demolition.

- The technique supports diverse applications, including underwater cutting and structural dismantling, bringing unmatched versatility to the demolition field.

- Ongoing innovations in diamond wire saw technology are forecasted to yield even greater improvements in efficiency, safety, and sustainability.

Introduction to Diamond Wire Saw Cutting

Industrial demolition has seen a transformative shift in recent years, and one technology leading this revolution is diamond wire saw cutting. This method, relying on a wire embedded with ultra-hard diamond segments, enables workers to slice through concrete and steel with extreme precision. Unlike older demolition methods that often caused excessive dust, noise, and physical stress on structures, diamond wire saw cutting delivers clean cuts while reducing collateral damage and enhancing site safety from the outset.

The process is rapidly replacing traditional wrecking and sawing techniques across industries ranging from civil construction to offshore energy infrastructure. Contractors and engineers increasingly rely on this advanced solution for its ability to meet tight tolerances, ensure safety, and minimize disruption to surrounding environments and structures.

Understanding the Diamond Wire Sawing Process

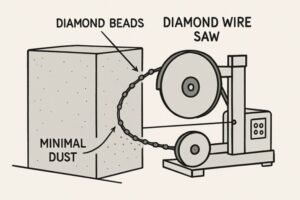

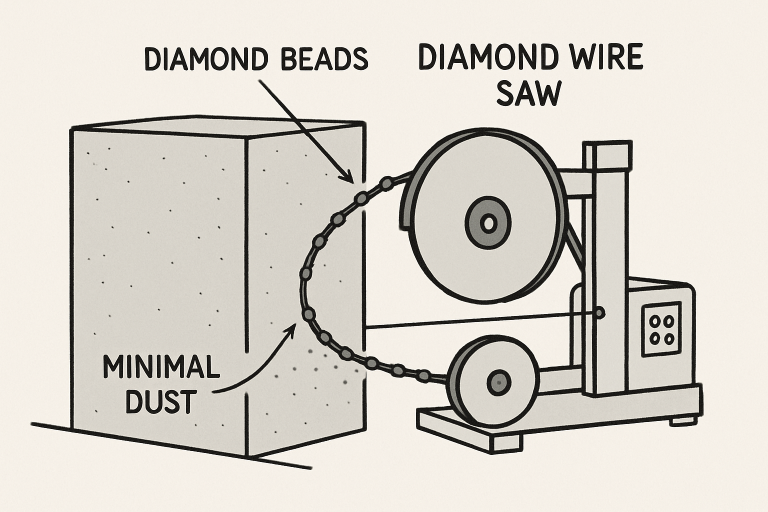

At the core of diamond wire saw cutting is a flexible steel wire, encrusted with industrial-grade diamond beads, which is guided through pulleys around the targeted cutting area. As the machine powers the wire in a continuous loop, the diamond segments grind through even the densest materials, providing steady and controlled progress with each pass. Technicians can adjust the angle and orientation of the wire or alter the tension to tailor the cut to project-specific requirements, as noted in research on advancements in cutting technology published by ScienceDirect. This adaptability enables teams to undertake complex cuts, whether dealing with vertical, horizontal, or even submerged structures. The efficient cooling provided, often using water, keeps dust levels low and ensures equipment performs optimally during operation.

Key Advantages of Diamond Wire Saw Cutting

- Precision and Accuracy: The diamond wire is capable of delivering surgical accuracy, resulting in minimal waste and virtually no overcut. This high degree of control is essential for projects that require exact measurements, as well as for minimizing repairs or finishing work after demolition.

- Reduced Noise and Vibration: Compared to traditional saws or jackhammers that generate substantial noise and vibrations, diamond wire saws are remarkably quiet and gentle. This quality is increasingly valuable in urban or sensitive environments where noise pollution and structural stability are major concerns, as highlighted by publications such as e-architect.

- Versatility: The technology can be applied to a wide range of materials, including concrete with any type of reinforcement, natural stone, and metals such as steel or iron. No matter the demands of a construction, infrastructure, or industrial site, diamond wire saws can adapt without the need for costly tool changes.

- Environmental Benefits: In addition to reducing dust and airborne contaminants, diamond wire sawing facilitates better debris management and generates less disposable waste, resulting in a cleaner and safer work zone.

Applications in Industrial Demolition

Diamond wire saw cutting’s scope is broadening as industrial demolition projects become more complex and safety-conscious:

- Building Demolition: It allows for selective deconstruction, ensuring that only targeted sections are removed while preserving the remainder of the structure or minimizing impact on adjacent properties.

- Bridge Deconstruction: This technique is ideal for the segmental removal of bridge decks, piers, and abutments, allowing for the continued use of other sections and reducing the risk to traffic and workers.

- Underwater Cutting: In marine and offshore applications, such as cutting piles, pipelines, or caissons, diamond wire sawing excels where other tools cannot operate due to flooding, depth, or confined conditions.

Safety Considerations and Best Practices

Despite the inherent strengths of diamond wire saw cutting, strict attention to safety remains vital. Operators must receive comprehensive training in setup, monitoring, and emergency procedures to minimize risks such as wire breakage, flying debris, or entanglement. Personal protective equipment (PPE), including face shields, gloves, and hearing protection, is essential at all times. Regular inspection and maintenance routines extend the life of both the machine and wire, while robust job planning ensures hazards are identified and controlled before cutting begins.

Future Prospects of Diamond Wire Saw Cutting

The pace of innovation in diamond wire saw technology is accelerating. Automatic tensioning systems are being integrated to optimize cut quality and extend wire life. Improvements in diamond bead composition lead to even greater durability and cutting efficiency. Remote-controlled and robotic setups now enable the conduct of cutting operations in hazardous or hard-to-reach areas, thereby further amplifying both safety and productivity. These advances ensure that diamond wire saws will remain at the forefront of sustainable and safe industrial demolition for years to come.

Conclusion

Diamond wire saw cutting has transformed industrial demolition, offering an ideal blend of accuracy, adaptability, and environmental responsibility. Whether faced with sensitive urban demolitions, bridge deconstructions, or challenging underwater projects, this technique consistently delivers precise and safe results. As technology continues to evolve, diamond wire saw cutting will undoubtedly set new benchmarks in efficiency and performance across the demolition industry.